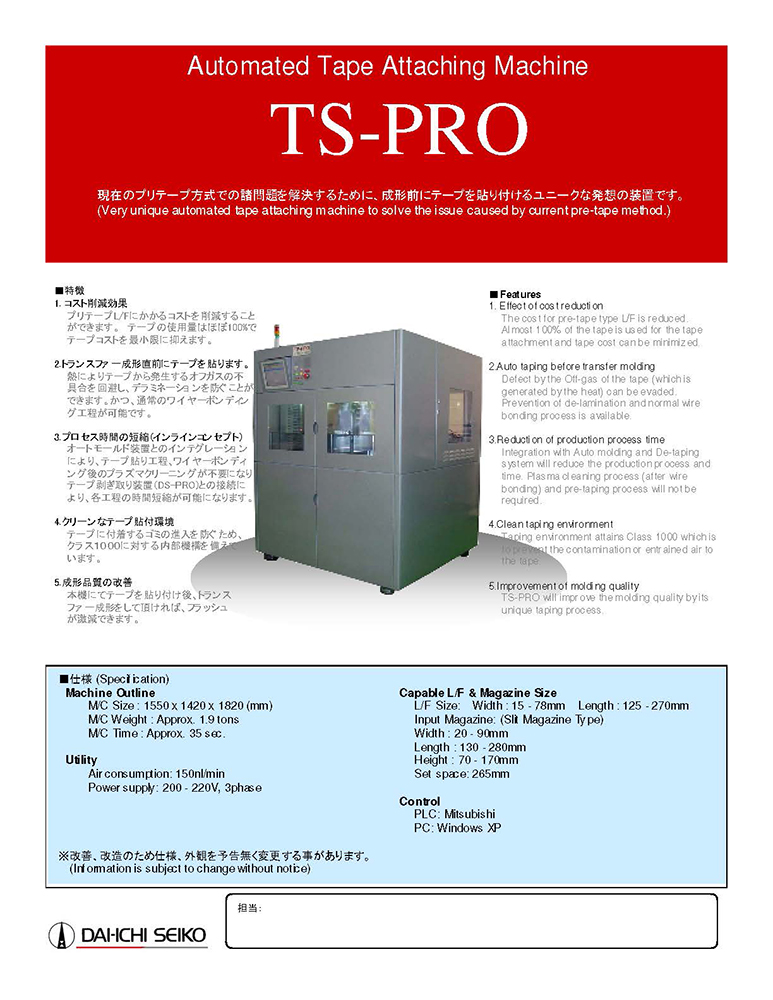

產品說明

- Auto taping before transfer molding :

Defect by the Off-gas of the tape (which is generated by the heat) can be evaded and occurrence of delamination is prevented.

As normal wire bonding process is available, yield loss caused by wire bonding on taped L/F is prevented. - Reduction of production process time :

Integration with Auto Molding System and Auto De-taping System will reduce the production process and time. Plasma cleaning process (after wire bonding) and pre-taping process will not be required. - Clean taping environment :

Taping environment attains Class 1000 which is to prevent the contamination or entrained air to the tape. - Improvement of molding quality :

TS-PRO will improve the molding quality by its unique taping process. - Effect of cost reduction :

The cost for pre-tape type L/F is reduced. Almost 100% of the tape is used for the tape attachment and tape cost can be minimized.

| Machine time | 35 sec. (Approx.) |

| Machien size&weight | W : 1550mm, L : 1420mm, H : 1820mm / 1.9 ton |

| Max. Leadframe size | 75mm x 270mm |